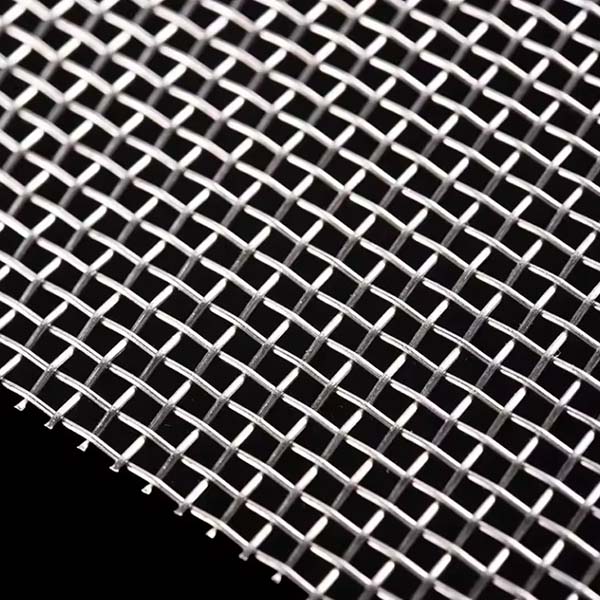

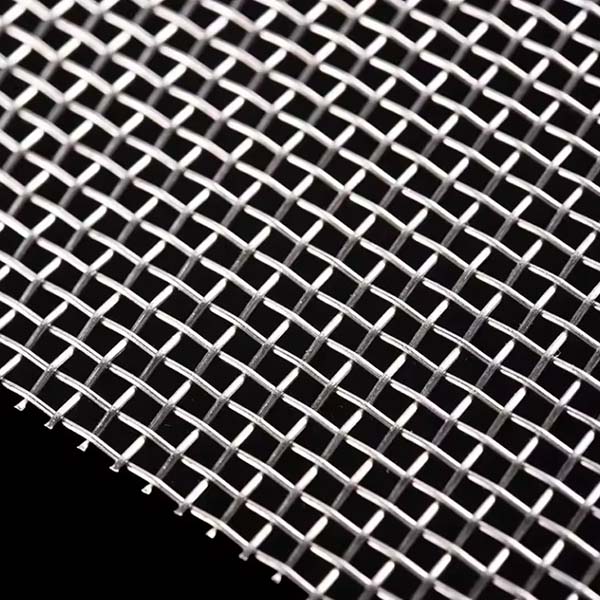

Twill Dutch woven mesh, each warp and weft is located on the two adjacent complementary lines below, just like a regular diagonal weave, except that the diameter of the warp is larger than that of the weft. This increases the number of mesh in the latitude direction. This weaving method can make the weft threads denser and achieve smaller aperture sizes without affecting the thickness of the fabric

Material

Galvanized, stainless steel wire (SUS201, SUS304, SUS316, SUS304L, SUS316L, SUS310, SUS310s, SUS430 and other stainless steel grades)

Features

Precise structure, uniform mesh, good filtration accuracy, wear resistance, high temperature resistance, strong acid resistance, and corrosion resistance

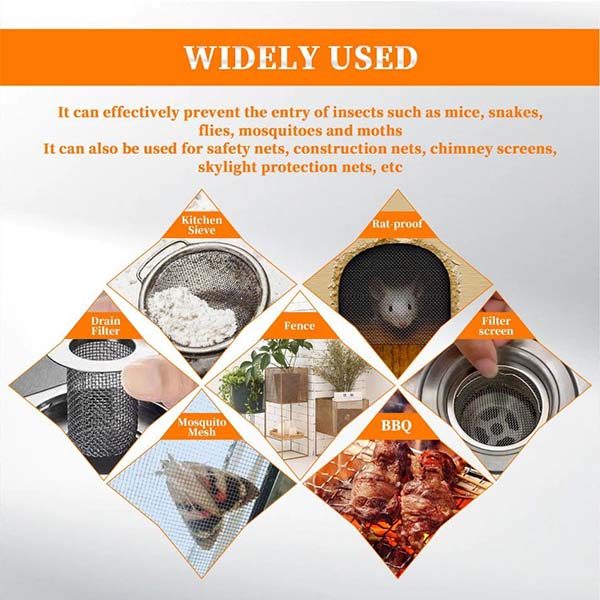

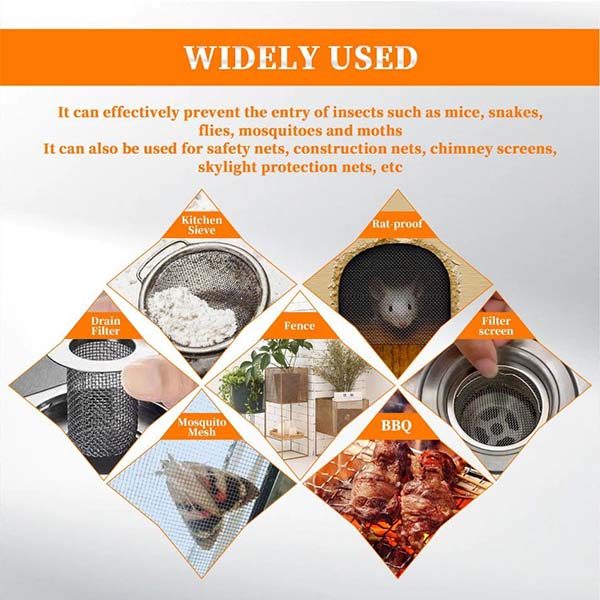

Usage

1. Used for screening and filtering under acidic and alkaline environmental conditions, in the petroleum industry as a mud net, chemical fiber industry as a screening filter, electroplating

2.Used in industries such as mining, petroleum, chemical, food, medicine, and machinery manufacturing

3.Used for screening and filtering under acidic and alkaline environmental conditions, used as mud screens in the petroleum industry, screens in the chemical fiber industry, and acid washing screens in the electroplating industry. Our factory can design and produce various types of products according to user needs

Size

Customizable according to customer requirements (stock also available).