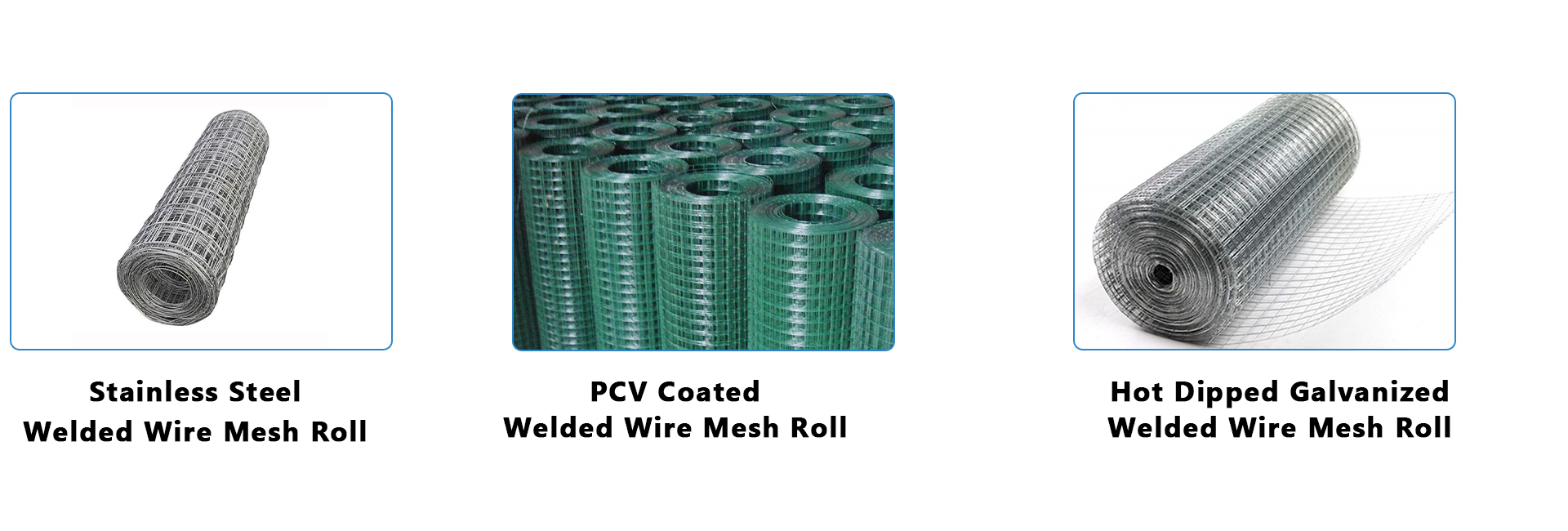

Stainless steel welded wire mesh is a strong and durable metal mesh made by welding stainless steel wires at their intersections. It is widely used in industrial, agricultural, construction, and security applications due to its excellent strength, corrosion resistance, and versatility.

Material

Galvanized, stainless steel wire (SUS201, SUS304, SUS316, SUS304L, SUS316L, SUS310, SUS310s, SUS430 and other stainless steel grades)

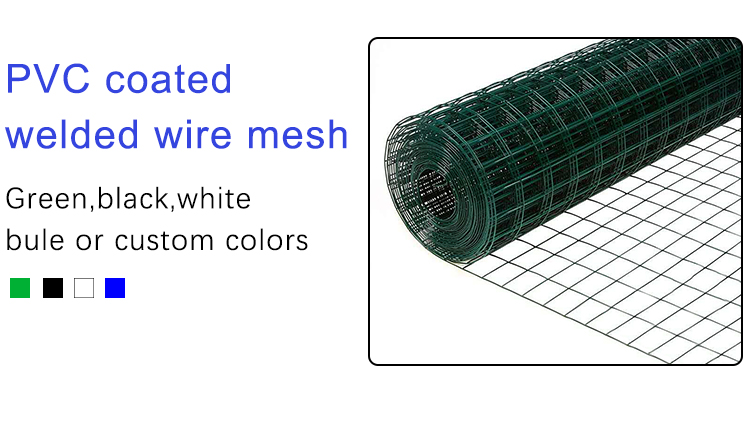

Coated:PVC Coated,Hot dip galvanizing,electric galvanizing

Features

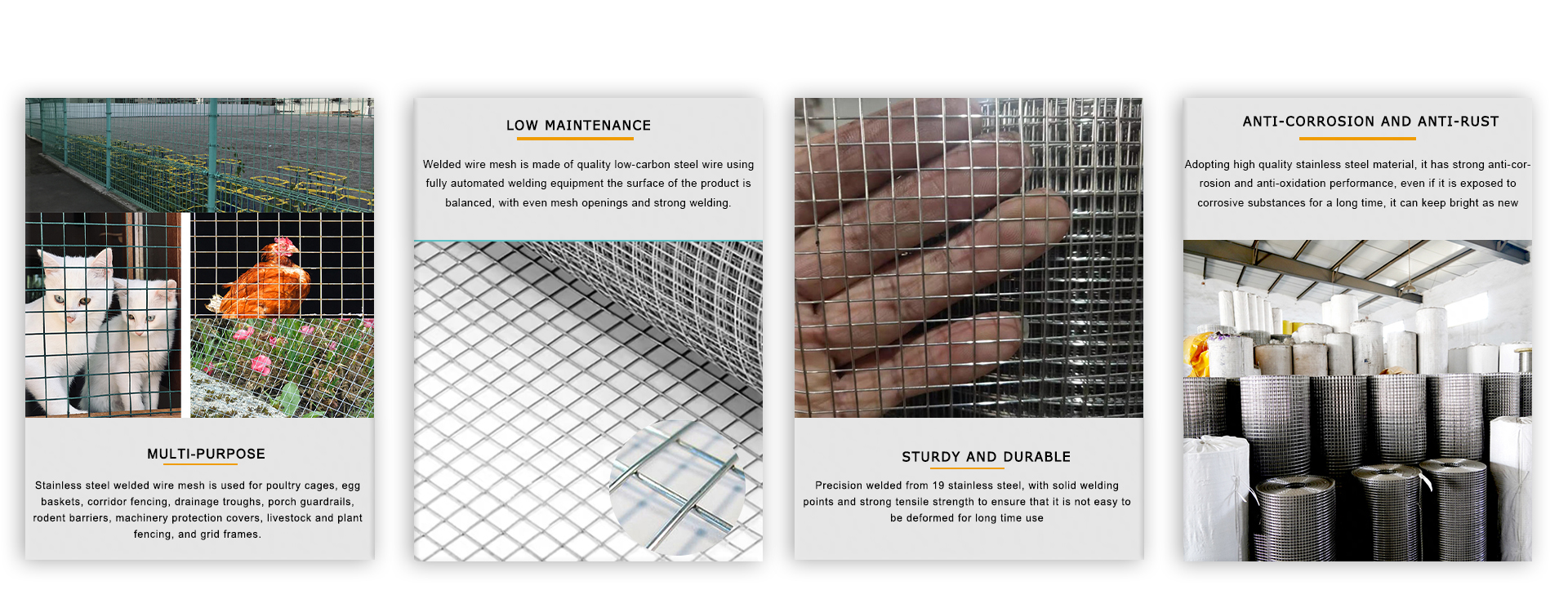

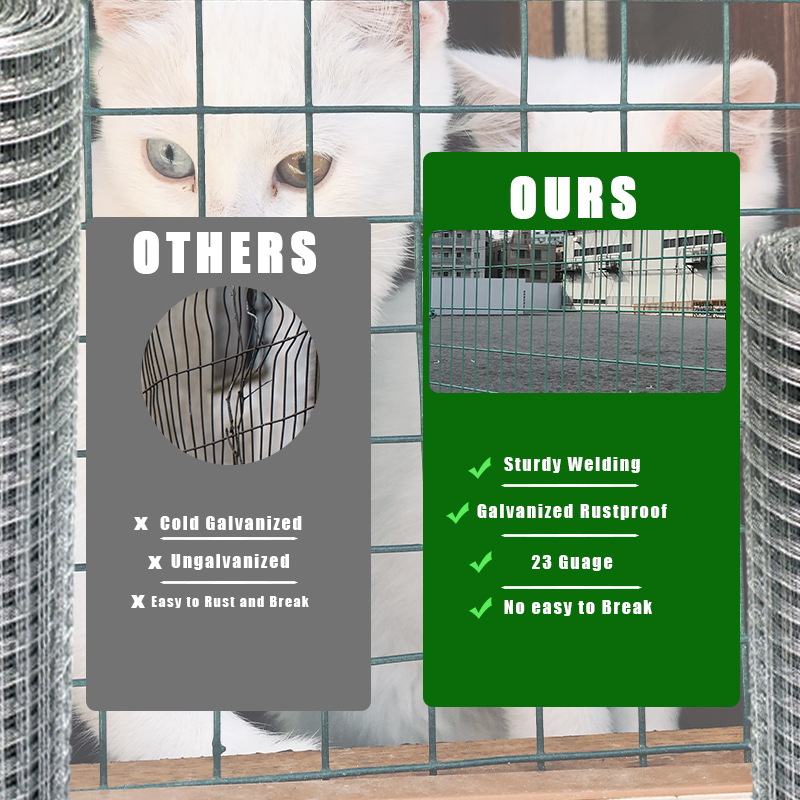

Galvanized welded mesh, made of high-quality galvanized wire strands, is more acid resistant, alkali resistant, firmly welded, beautiful, and widely used

High Corrosion Resistance – Made from stainless steel (such as 304, 316, or 316L), it withstands harsh environments, including exposure to moisture, chemicals, and extreme temperatures.

Strong and Rigid Structure – The welding process ensures firm intersections, providing high tensile strength and preventing wire movement for enhanced durability.

Excellent Security and Protection – The rigid structure makes it ideal for fencing, enclosures, and safety barriers in industrial and residential settings.

Good Airflow and Visibility – The open mesh design allows proper ventilation and visibility while maintaining security.

Easy to Install and Maintain – Can be cut, bent, and shaped as needed, with a smooth, easy-to-clean surface that resists rust and wear.

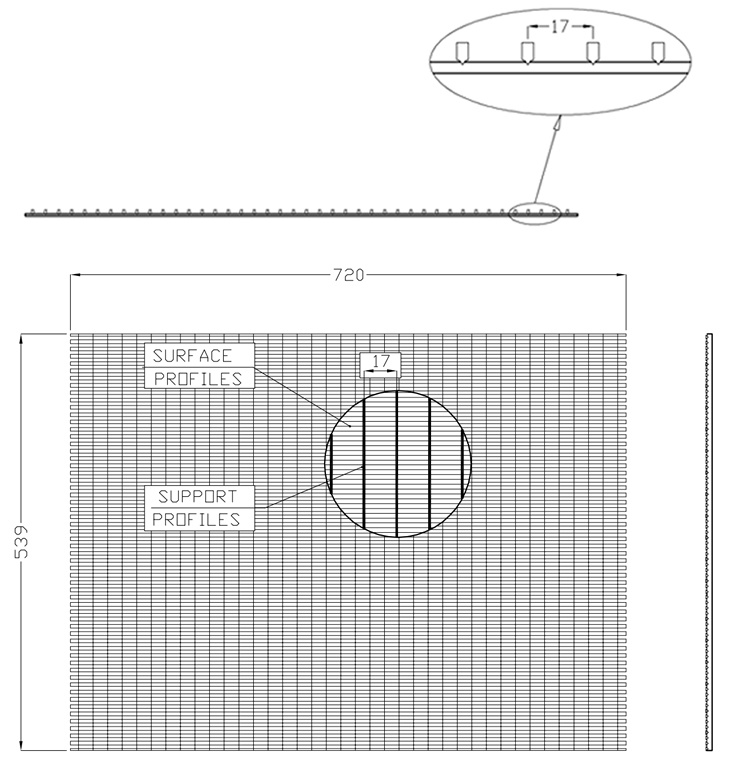

Available in Various Specifications – Offered in different wire diameters, mesh sizes, and panel dimensions, with options for rolls or sheets to suit different applications.

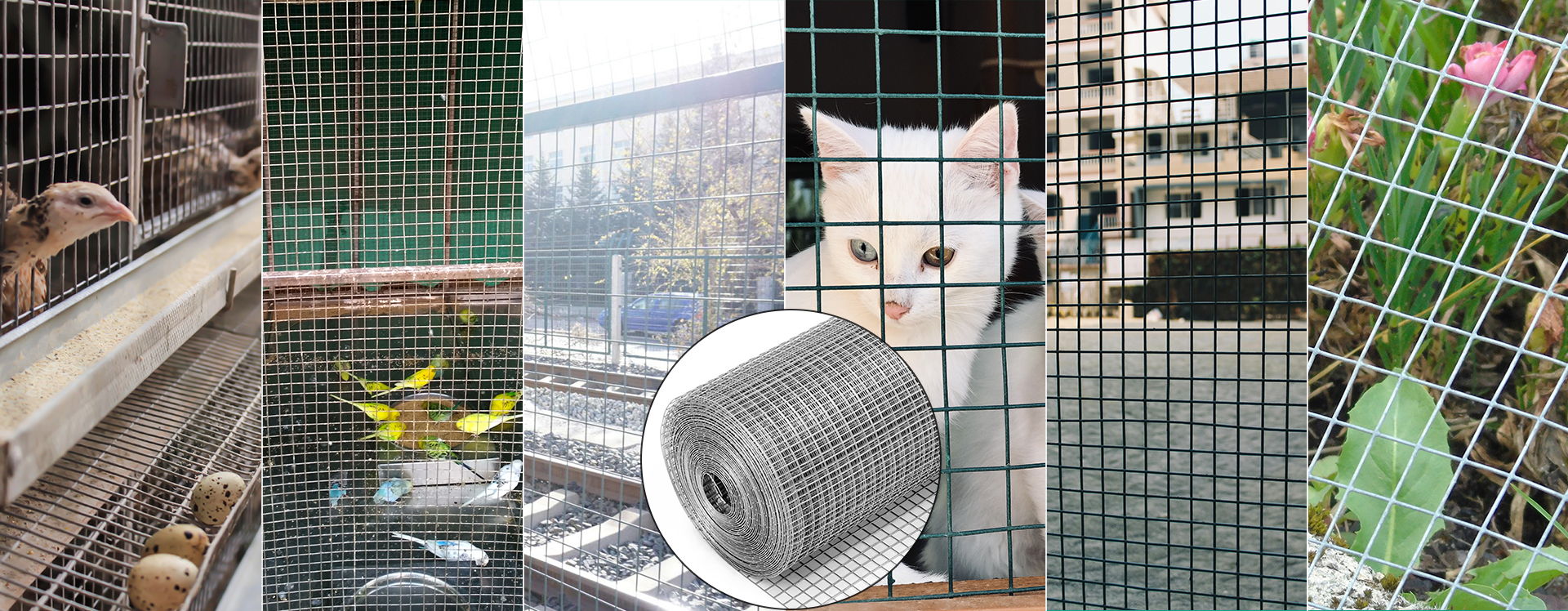

Application

Industrial & Agricultural Use – Machine guarding, greenhouse benches, and livestock enclosures.

Construction & Infrastructure – Concrete reinforcement, wall support, and drainage systems.

Security & Fencing – Perimeter fences, window guards, and protective barriers.

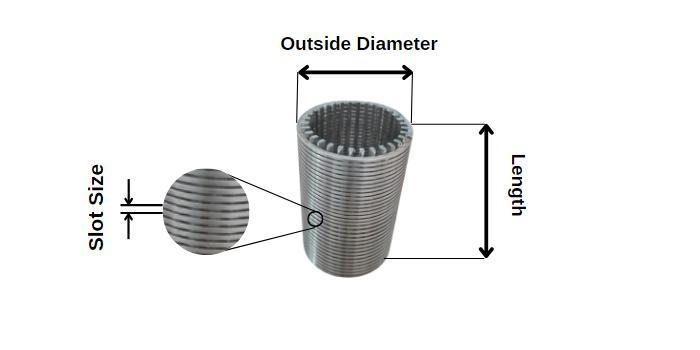

Filtration & Separation – Used in mining, oil refining, and wastewater treatment.

Stainless steel welded wire mesh is an ideal choice for applications requiring strength, longevity, and resistance to corrosion. It is customizable based on specific project needs.