Stainless Steel Woven Wire Mesh/Cloth

Product introduction

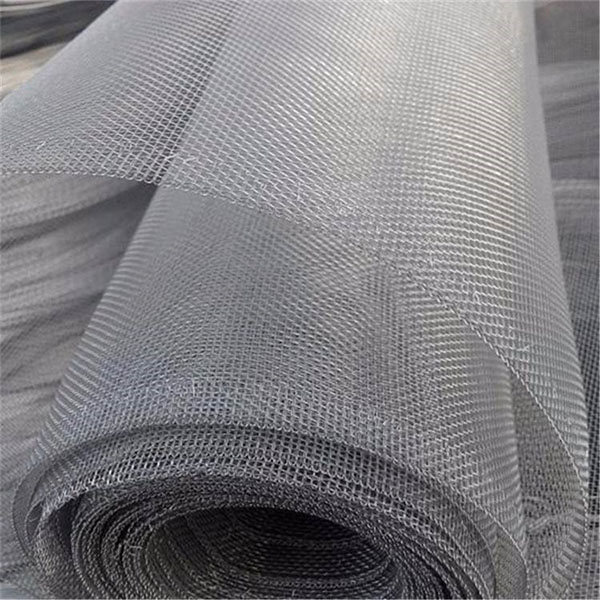

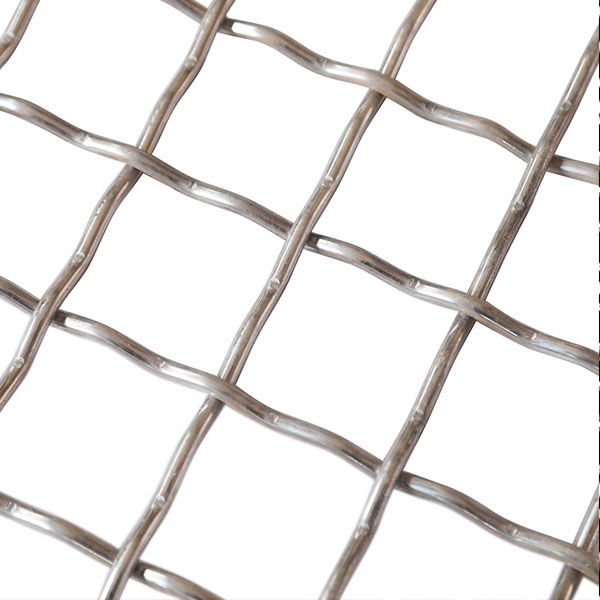

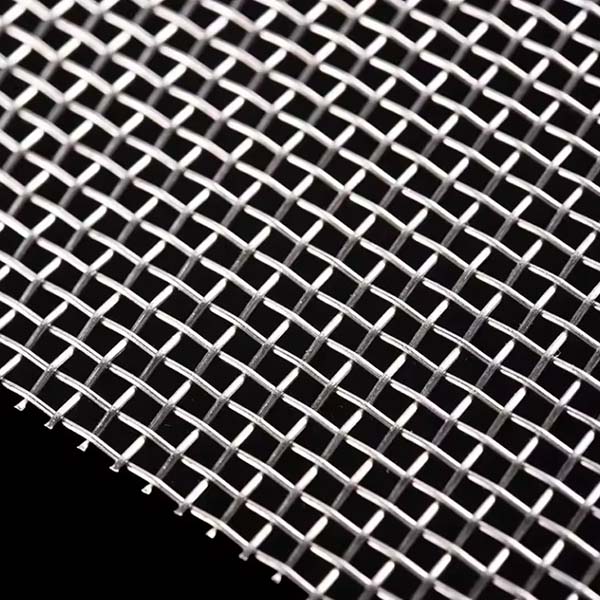

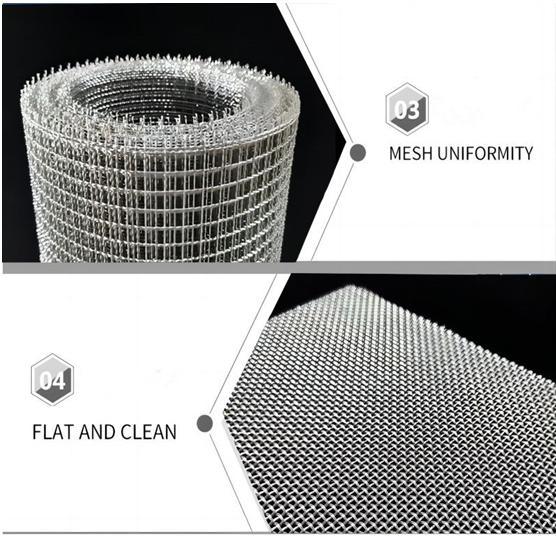

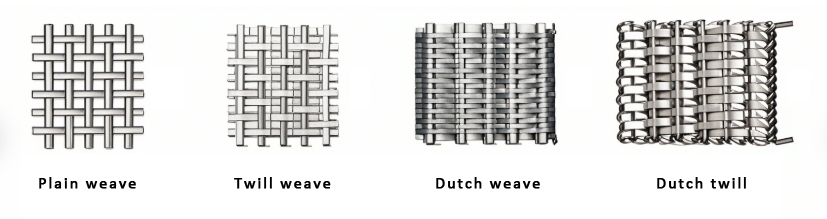

Woven wire mesh products, also known as woven wire cloth, are woven on looms, a process that is similar to the one used to weave clothing. The mesh can consist of various crimping patterns for the interlocking segments. This interlocking method, which entails the precise arrangement of the wires over and under one another prior to crimping them into place, creates a product that’s strong and reliable. The high-precision manufacturing process makes woven wire cloth more labor-intensive to produce therefore it is typically more expensive than welded wire mesh.

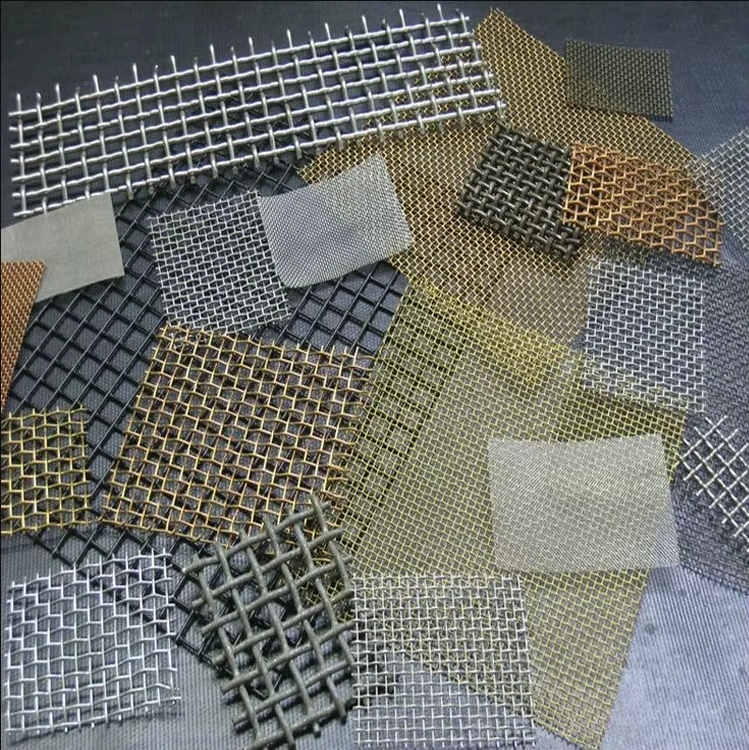

Stainless steel woven wire mesh is a remarkable product crafted through a meticulous process. It starts with high – grade stainless steel wires, which are carefully selected for their purity and composition. Material include:Galvanized, stainless steel wire (SUS201, SUS304, SUS316, SUS304L, SUS316L, SUS310, SUS310s, SUS430 and other stainless steel)

Stainless steel woven wire mesh comes in various specifications, including wire diameter, mesh size, open area, and weaving type, which can be customized to meet specific requirements.

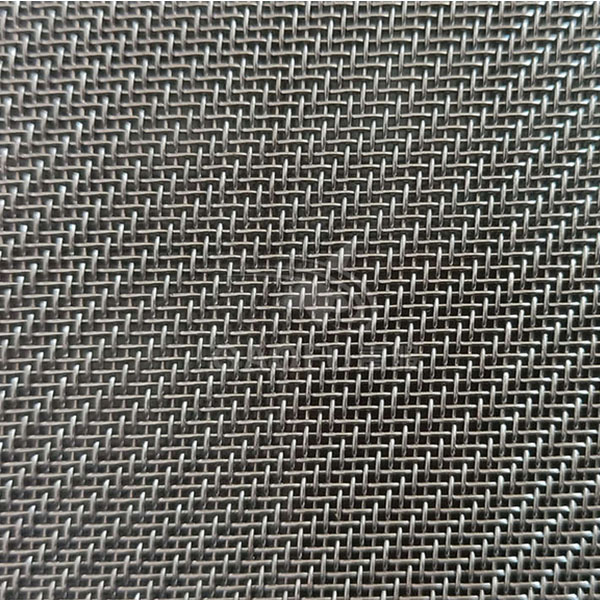

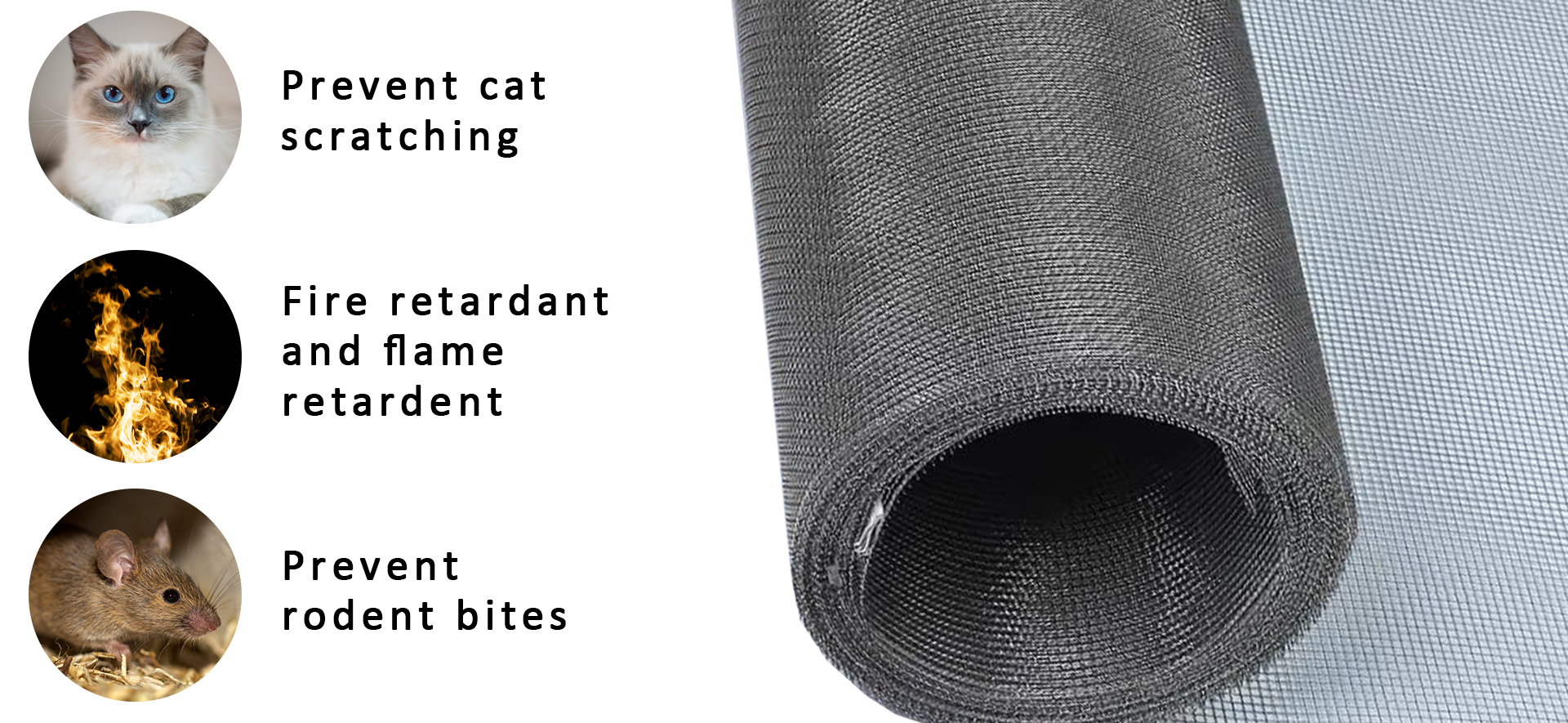

Made of 304 stainless steel, abrasion-resistant, heat-resistant, low temperature-resistant, with excellent fire performance. Environmentally friendly materials, mesh smooth and fine, bright colours, for you to create a safe and comfortable home environment.

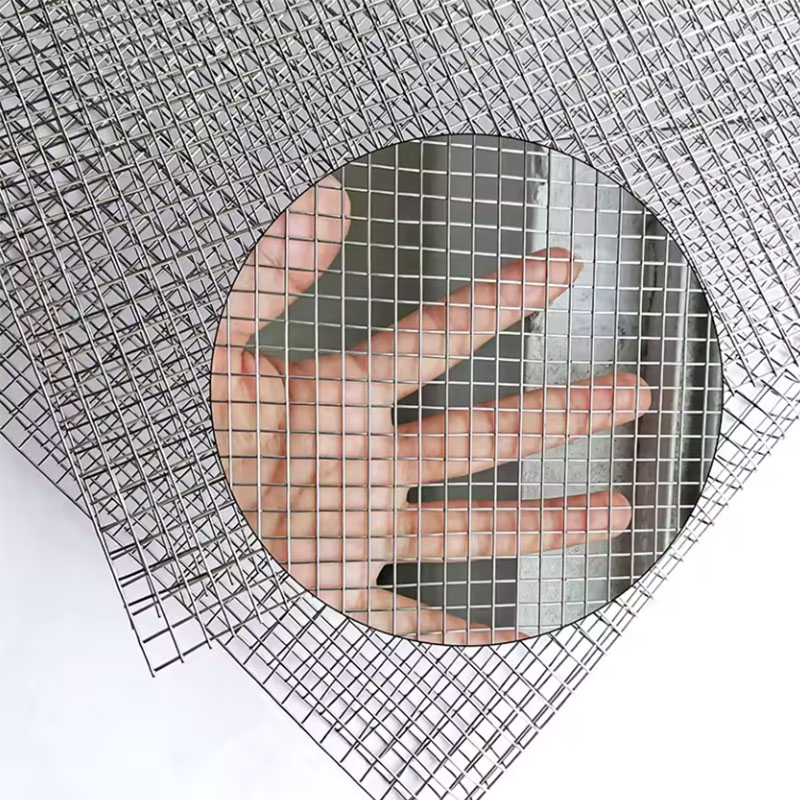

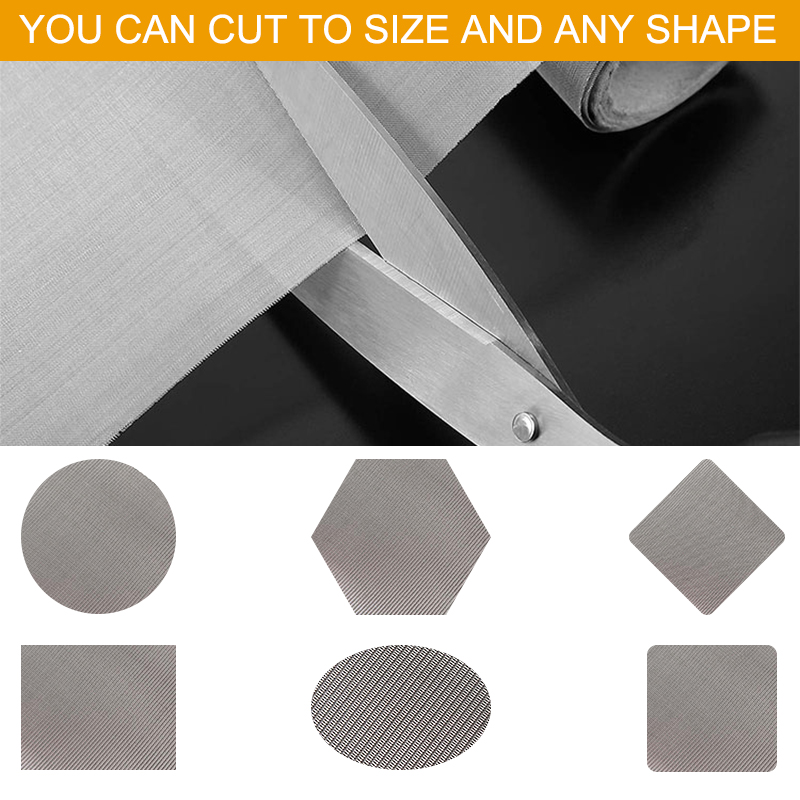

Can be cut to size according to your actual needs, both for the replacement of old screens, can also be used as a new screen, the installation process is simple, easy to dismantle and clean, so that you can easily enjoy an efficient life.

Stainless steel woven wire mesh comes in various specifications, including wire diameter, mesh size, open area, and weaving type, which can be customized to meet specific requirements.

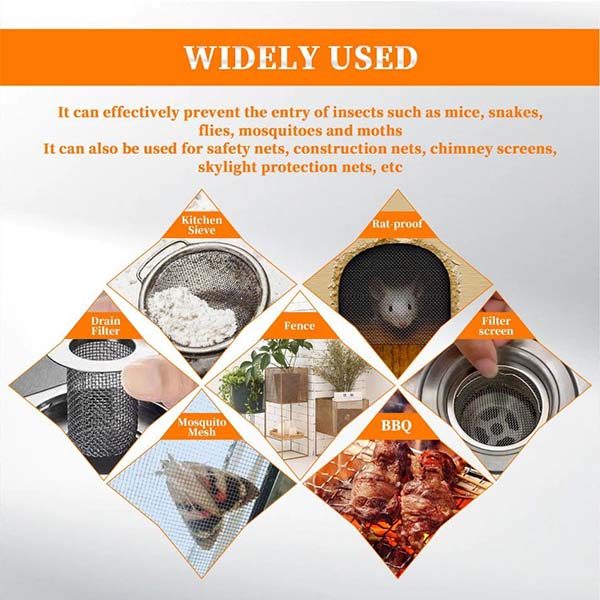

Application

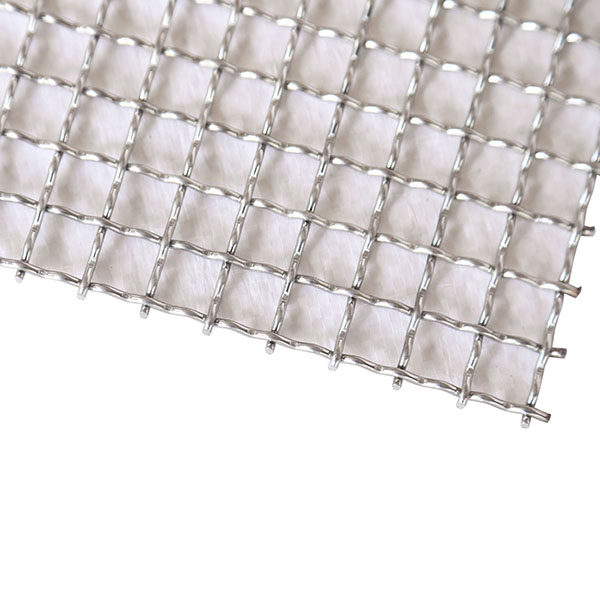

Wide usage-Can work as mesh, suitable for crawl space vent repair, cabinet wire mesh, animal cage net, etc; The mesh is small but strong enough so that they can work effectively for a long time

Wide application- This mesh can used for plastic repair, mending windows and doors, construction and building meshes, fan guard mesh, fireplace screen mesh, foundation vent meshes, garden use mesh, gutter guard mesh, cabinets mesh, door screen mesh etc

Custom size

Contact us for more sizes

| Woven mesh | |||

| Specification | Wire diameter(mm) | aperture(mm) | weight(kg) |

| Width: 1m | 0.5 | 1 | 63 |

| Width: 1m | 0.6 | 1 | 66 |

| Width: 1m | 0.8 | 1 | 113 |

| Width: 1m | 0.7 | 1 | 84 |

| Width: 1m | 0.5 | 1.6 | 36 |

| Width: 1m | 0.6 | 1.6 | 43 |

| Width: 1m | 0.7 | 1.5 | 70 |

| Width: 1m | 0.5 | 1 | 55 |

| Width: 1m | 0.7 | 2.5 | 43 |

| Width: 1m | 0.8 | 2.25 | 59 |

| Width: 1m | 0.8 | 2.25 | 63 |

| Width: 1m | 1 | 2.2 | 105 |

| Width: 1m | 1 | 2 | 112 |

| Width: 1m | 1 | 1.6 | 127 |

| Width: 1m | 0.8 | 2 | 74 |

| Width: 1m | 0.8 | 2 | 78 |

| Width: 1m | 0.8 | 2 | 79 |

| Width: 1m | 0.7 | 2 | 57 |

| Width: 1m | 0.7 | 2 | 58 |

| Width: 1m | 0.6 | 2 | 41 |

| Width: 1m | 1 | 3 | 76 |

| Width: 1m | 1 | 3 | 82 |

| Width: 1m | 0.9 | 3 | 60 |

| Width: 1m | 0.6 | 3 | 27 |

| Width: 1m | 1.5 | 3 | 168 |

| Width: 1m | 2 | 3 | 268 |

| Width: 1m | 1 | 3 | 72 |

| Width: 1m | 1.2 | 3 | 115 |

| Width: 1m | 0.8 | 3 | 52 |

| Width: 1m | 0.8 | 3 | 47 |

| Width: 1m | 0.7 | 4 | 30 |

| Width: 1m | 0.8 | 4 | 48 |

| Width: 1m | 1 | 4 | 62 |

| Width: 1m | 1.2 | 4 | 89 |

| Width: 1m | 2 | 4 | 221 |

| Width: 1m | 1.5 | 4 | 139 |

| Width: 1m | 1.2 | 5 | 75 |

| Width: 1m | 1.2 | 5 | 71 |

| Width: 1m | 1 | 5 | 53 |

| Width: 1m | 1 | 5 | 51 |

| Width: 1m | 2 | 5 | 118 |

| Width: 1m | 0.7 | 5 | 27 |

| Width: 1m | 1.5 | 5 | 114 |

| Width: 1m | 0.8 | 5 | 32 |

| Width: 1m | 0.9 | 5 | 41 |

| Width: 1m | 0.8 | 6 | 27 |

| Width: 1m | 2 | 6 | 157 |

| Width: 1m | 1.5 | 6 | 103 |

| Width: 1m | 1.2 | 6 | 67 |

| Width: 1m | 0.9 | 6 | 38 |

| Width: 1m | 1 | 6 | 48 |

| Width: 1m | 1 | 6 | 46 |

| Width: 1m | 1 | 8 | 33 |

| Width: 1m | 1 | 8 | 34 |

| Width: 1m | 1 | 8 | 37 |

| Width: 1m | 1.2 | 8 | 53 |

| Width: 1m | 1.2 | 8 | 51 |

| Width: 1m | 1.5 | 8 | 82 |

| Width: 1m | 2 | 8 | 128 |

| Width: 1m | 1 | 10 | 29 |

| Width: 1.2m | 0.6 | 1 | 84 |

| Width: 1.2m | 0.7 | 2 | 70 |

| Width: 1.2m | 0.69 | 2 | 46 |

| Width: 1.2m | 0.6 | 2 | 48 |

| Width: 1.2m | 0.8 | 2 | 92 |

| Width: 1.2m | 0.8 | 2 | 89 |

| Width: 1.2m | 0.7 | 2.5 | 52 |

| Width: 1.2m | 0.7 | 2.5 | 53 |

| Width: 1.2m | 0.8 | 2.5 | 66 |

| Width: 1.2m | 1 | 2 | 135 |

| Width: 1.2m | 0.8 | 3 | 63 |

| Width: 1.2m | 1 | 3 | 101 |

| Width: 1.2m | 0.7 | 4 | 38 |

| Width: 1.2m | 1 | 4 | 76 |

| Width: 1.2m | 1.2 | 4 | 107 |

| Width: 1.2m | 0.9 | 5 | 50 |

| Width: 1.2m | 1 | 5 | 64 |

| Width: 1.2m | 1.2 | 5 | 91 |

| Width: 1.2m | 1.2 | 5 | 87 |

| Width: 1.2m | 2 | 5 | 222 |

| Width: 1.2m | 0.9 | 5 | 45 |

| Width: 1.5m | 0.6 | 2 | 62 |

| Width: 1.5m | 0.8 | 2 | 112 |

| Width: 1.5m | 1 | 3 | 109 |

| Width: 1.5m | 1 | 4 | 92 |

| Width: 1.5m | 0.8 | 5 | 47 |

| Width: 1.5m | 1 | 5 | 77 |

| Width: 1.5m | 1 | 5 | 74 |

| Width: 1.5m | 1.2 | 5 | 109 |

| Width: 1.5m | 1.5 | 5 | 169 |